Dept. of Transportation regulations state that any and all lights on a vehicle must be in working order. Phillips Industries notes that trailer lights function properly when they are free from damage, installed correctly and receive the proper amount of power needed to operate. A clear pathway for electricity to flow to the lights on any trailer begins with a solid, corrosion free, seven-way electrical connection. The electrical pathway beyond the seven-way connection is then responsible for carrying power to the lights. However, to function at its best, the electrical harness system, from the socket connection at the front, all the way back to the farthest light, must be free from corrosion. Additionally, any new electrical connections created within a harness when repairs are made, (including socket replacement) should be done correctly to avoid vulnerability to moisture and contaminants, which can lead to corrosion. Once corrosion enters the electrical system, it has the potential to spread quickly, hindering the flow of power to the lights. Lighting and pigtail connections are just as equally important as the seven-way connection. Pigtails that are securely connected to the light, and clean from moisture, dirt and debris, help to keep trailer lighting functioning properly.

When wiring a socket to the trailer’s electrical harness it’s important to keep in mind that proper wire insertion, as well as the different types of  connections available, can affect the overall “health” of the electrical system. When done incorrectly, or if the connections are left exposed to corrosion causing elements, the driver is put at risk for possible CSA vehicle maintenance violations due to flickering and/or inoperable lights. To avoid any mishaps from these types of electrical socket wiring connections, Phillips recommends a sealed harness system with a bulleted socket.

connections available, can affect the overall “health” of the electrical system. When done incorrectly, or if the connections are left exposed to corrosion causing elements, the driver is put at risk for possible CSA vehicle maintenance violations due to flickering and/or inoperable lights. To avoid any mishaps from these types of electrical socket wiring connections, Phillips recommends a sealed harness system with a bulleted socket.

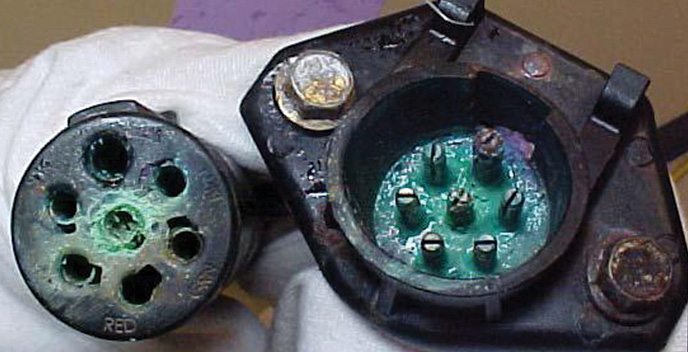

Corrosion has a more devastating effect. When corrosion begins to take over, the copper surface of the pins on the plugs and sockets, as well as the wires in the electrical cables and/or harness system, become diminished. Fewer electrons are able to flow over the surface, causing resistance and a drop in voltage. Voltage drop due to corrosion may become apparent when lights dim, flicker or go out altogether. On the inside of a trailer, dome lights may experience the same effect. Maintaining the electrical system to keep it free from corrosion is very important to help avoid this.

A strong connection at the pigtails keeps lights from flickering and going out due to road vibration that can cause loose connection overtime. A strong connection also keeps out contaminants that will affect the proper operation of the lights. Any moisture or contaminant that enters the trailer wiring at the connections, or at the area surrounding the light itself, will cause a failure that will ultimately result in CSA points being assessed.