- India

- International

A Town Goes Into Hiding

Kolhapur may have lent its name to the famous chappal, but the industry has taken a hit with the rise of cow vigilantes.

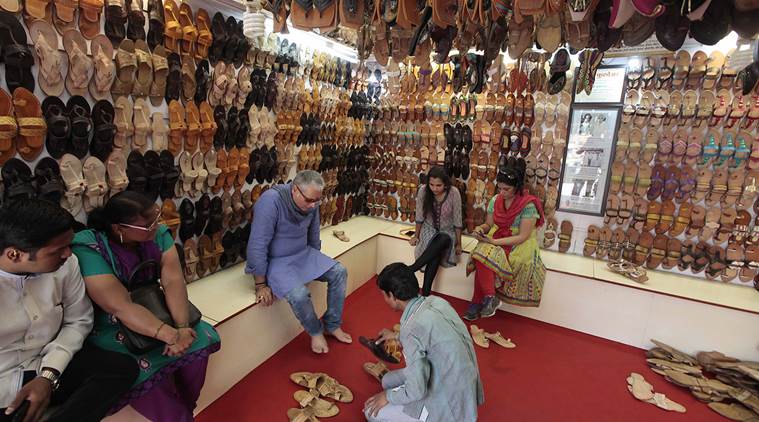

Feeling the pinch: Customers trying out slippers at a store in Kolhapur’s Chappal Gali. (Source: Express photo by Pavan Khengre)

Feeling the pinch: Customers trying out slippers at a store in Kolhapur’s Chappal Gali. (Source: Express photo by Pavan Khengre)

In a small room in Chappal Gali in Kolhapur, five men are seated on the floor, stitching and designing the traditional handcrafted slippers that are named after the town they are manufactured in. One of them fixes the strap on the slipper, another draws the pattern of the sole on a thick buffalo hide, while a third sticks the two layers of the sole together. Rajendra Namdeo Kadam’s unit is one of the 50-odd shops that is still in business in the famous Chappal Gali but is battling a crisis made worse after tanneries have closed down following threats by cow vigilantes.

Even before the vigilantes arrived, the industry was already in the red. Over the last few years, the Maharashtra Pollution Control Board (MPCB) has shut down many units for violating green norms. The remaining shut shop after suppliers stopped sending them hides once the ban on slaughter of cow, bulls, calves and oxen came into effect in Maharashtra in March 2015. Though the ban shouldn’t have affected the manufacture of Kolhapuri slippers given that they use leather that comes from the buffalo hide, such was the fear following threats by gau rakshaks, that the suppliers stopped sending hide altogether. Kolhapur, which once had 46 tanning units, has none now and the makers of Kolhapuri chappals, once a must-have in every college student’s closet, have now turned to suppliers outside the state, jacking up the price of the slipper by almost 20 per cent.

Kadam ran a tanning unit too but was forced to shut it after the ban on slaughter. “The skin of animals like the buffalo and goat can be used after they die and we used it to make Kolhapuris. But ever since the beef ban has come into effect, nobody is ready to touch the carcass of any animal. We were asked to shut the units on the charges of ‘pollution’, despite the fact that unlike some of the tanning units of Karnataka which use chemicals for processing, all the material we used in the bag tanning process are natural and wasn’t harmful for the environment,” said Kadam. After his tanning unit shut, Kadam started sourcing raw material from Nipani in Karnataka, a town that is half-an-hour away from Kolhapur.

But the worst hit, perhaps, is the community that has been involved traditionally with the making of Kolhapuri chappals. While there are around 10,000 Dhors spread across Kolhapur engaged in different professions, nearly a thousand worked in the tanning industry. Many of them have found new jobs and are migrating to other villages. Shahji Suresh Tapase, a member of the Dhor community, who once had a thriving business, points to an abandoned plot which once was a buzzing tanning unit that processed hide, and frowns. His unit in Jawaharnagar stands desolate like many others in the town.

“It all happened gradually. Ever since news about gau rakshas carrying out raids and beating people started doing the rounds, people who used to supply us skin of dead buffaloes, stopped out of fear. And after that, we were asked to close down our unit,” said Tapase.

Before it went quiet, Kolhapur’s tanning units hummed busily, processing hides and sending the leather to artisans to be crafted into the popular Kolhapuris. The month-long procedure involved soaking the hide for 15 days in water with limestone, which was followed by soaking it in water with babul (acacia) for another week before it got a final soak for a week in water mixed with hirda (terminalia chebula).

Kolhapuris come in a variety of designs —Shahu, Kurundwad, Kaapsi — and cost anything between Rs 250 and Rs 7,000 for a pair. Vicky Powar, an artisan, says typically Kolhapuris for men are more expensive than those for women because they are more intricate and take longer to make.

Tulsidas Vhatkar, who belongs to the Dhor community and ran a tannery before turning into a wholesaler of Kolhapuris, says the beef ban has caused problems for wholesalers too. “The initial few months were a huge struggle. We had to make fresh contacts with suppliers in Karnataka and build a rapport with them,” says Vhatkar. Apart from Nipani, Chennai is the other city wholesalers are looking at to get their leather supply.

But Vhatkar worries that Kolhapur is losing the connection with the slipper it gave its name to. “Earlier, the hide was bought from neighbouring villages, the tanning process was carried out in Kolhapur and finally the local artisans designed the slippers. The end result was the assal Kolhapuri (authentic Kolhapuri). Things have changed now. Now, many dealers are buying the processed hide from Karnataka and Chennai and are getting the chappals designed from local artistes of neighbouring states at cheaper rates and are selling them here as Kolhapuri chappals,” he says. The customers can’t differentiate between one made in Kolhapur and one made outside but Vhatkar insists there is one. “Slippers made with leather obtained after the bag tanning process have an edge over the others,” he says.

Small-time artisans are particularly finding the going tough. Ravi Singh, a cobbler who stitches and sells Kolhapuris , says, “It’s not difficult for wholesalers to get raw material in bulk from Karnataka. For individual chappal makers like us, it’s not affordable. Many have found new occupations, others like me are struggling.”

Ashok Shankar Gaikwad, president of the Kolhapur Charmodyog Samuh, an industrial cluster developed under Micro & Small Enterprises Cluster Development Programme (MSE-CDP), says the cluster had 3,000 local artisans associated with it earlier but many have turned to other jobs. “While many men now work as construction workers in and around Kolhapur, women have taken up jobs of housemaids. Currently, only 600 artisans of Kolhapur must be into stitching and designing Kolhapuris. The state government

should lift the ban and restart the tanneries so that Kolhapur’s legacy can be maintained,” says Gaikwad.

The Kolhapuri is fighting another battle for identity. In 2011, Leather Industries Development Corporation of Karnataka and Sant Rohidas Leather Industries Charmakar Development Corp Ltd (LIDCOM) Mumbai, jointly applied for the Geographical Indication (GI) status for the Kolhapuri chappal. However, it is yet to come through. “Going by the historical references, it is Kolhapur that should get the GI status for Kolhapuri chappals. Besides, the name itself is self-explanatory. The state government should take proactive stand and look at the long term interest of the artisans,” says Ganesh Hingmire, chairman of Pune-based Great Mission Group Consultancy, which deals with intellectual property rights, mainly focusing on GI and patents.

Meanwhile, in Kolhapur there is a rush of devotees at the famous Mahalaxmi Temple. After a visit to the temple, most tourists make it a point to visit Chappal Gali and buy the town’s most famous export. Kolhapur’s shoe industry is hoping it stays this way.

Apr 25: Latest News

- 01

- 02

- 03

- 04

- 05