Revealed: Greaves Cotton's all-new engine platform

Greaves Cotton is working on a new three-cylinder, 1.5-litre diesel motor which will help it cater to the passenger car and light commercial vehicle segments. Shobha Mathur has the details.

Greaves Cotton Ltd is working on a new three-cylinder, 1.5-litre diesel motor which will help it cater to the passenger car and light commercial vehicle segments. Shobha Mathur has the details.

Engine manufacturer Greaves Cotton, which was recently in the news for powering the new Multix personal utility vehicle from Eicher Polaris with a single-cylinder, 511cc BS-III diesel engine (10hp), is now transiting into the higher horsepower engine league.

The company is currently at an advanced stage of development of a new, larger diesel engine platform which could herald its entry into the passenger car and light commercial vehicle (LCV) segment from the small commercial vehicle (SCV) and three-wheeler space it currently caters to in the automotive engine market.

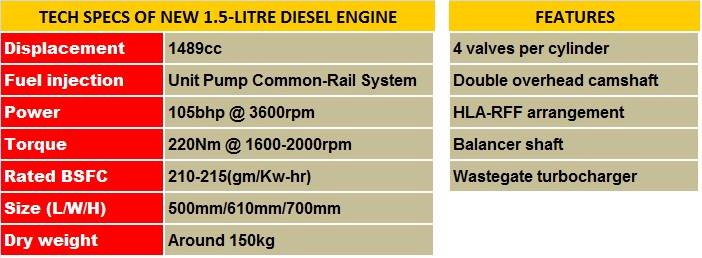

As part of its growth strategy, Greaves Cotton is now looking to move upwards in terms of offering its diesel engines from the sub-1-tonne payload capacity SCVs to 1T and 2-tonne payload capacity LCVs. Autocar Professional has learnt that Greaves Cotton is working on an all-new engine platform that involves developing a three-cylinder, 1.5-litre diesel engine which will be BS-V emission compliant, norms that are expected to be enforced by 2019.

Mohanjit Singh Walia, Chief Operating Officer of the company’s Engine Business Division, told this correspondent that the new engine platform will be modular with further variants evolving; one of them is likely to be a four-cylinder diesel motor. The 1.5-litre diesel engine will develop 105bhp and will be suited for meeting the higher power and torque requirements of both LCVs and passenger cars.

Developmental work on the prototype engine is slated to be completed by April-May 2016. Thereafter, the prototype will be available to vehicle manufacturers for further customisation and optimisation to meet their specific vehicle requirements.

The engine will further run through a minimum two-year cycle including testing and validation before it is ready for production. Greaves Cotton will be associated with vehicle OEMs (which deploy this engine) right through the modification stage, after which the power plant will be manufactured at the engine maker’s manufacturing facility.

Going forward, the focus will be on upping fuel economy and reducing CO2 emissions in engine development. Hence, the company’s thrust on turbo-charging and downsizing the engine for its future multi-cylinder engine project is integral. Being a cost-sensitive market, Greaves Cotton is optimistic of making its products cost effective by leveraging low cost technologies to meet stringent emission norms.

COMPACT MOTOR

Another aspect of the development of the multi-cylinder engine family has been making the engine very compact to facilitate easy packaging under the hood, even of cars. “Though we are in discussions with multiple parties on this topic, it’s very early to share any details,” adds Walia.

The company’s current crop of single- and double-cylinder engines target passenger and commercial vehicles up to 0.6T payload capacity and are compliant with BS-III emission norms. These are manufactured at its production facilities in Chennai and Aurangabad. At present, it does not have any product to cater to a category above 0.6T and the new addition will bridge this gap.

Above: The engine production line at Greaves Cotton's Chennai plant currently produces the 435cc engine which powers the Piaggio Ape three-wheeler and other small commercial vehicles in the Indian market.

A new production facility for manufacture of the new multi-cylinder engine platform is also on the drawing board, with a likely location being Aurangabad where the company’s technology centre is located. A team of 10 designers from this centre is believed to have been involved in the development of the new engine platform. While the technology roped in for development is in-house, Greaves Cotton has availed the services of consultants like FEV International for the development process.

For the present, the company’s technical centre is working on varied projects besides the new multi-cylinder engine family for instance, upgrading its single-cylinder engine for 0.6T SCVs as well as other BS-III engines to meet BS-IV emission standards. It is mulling various options to enhance the current product portfolio to be ready to meet evolving market demands post 2020 when the automotive market is pegged to reach 10 million units annually. The new emission upgrade projects will ensure longevity of the company’s existing product line-up.

“Our new BS-IV emission compliant engine development project is the culmination of our multiple years of experience in the single-cylinder engine domain and is available for all vehicles currently powered by the 511cc motor. Based on the specific requirements of each customer, the engine is customised to meet specific vehicle deliverables. The new engine is with common-rail technology to meet BS-IV norms with all-round enhancement in performance and fuel economy. This engine will replace the current 511cc engine once the BS-IV norms are in force. The key feature of the engine will be that it can be integrated on existing vehicle platforms without any major change in vehicle architecture,” adds Walia.

However, Greaves faces competition from captive engine manufacturing units of OEMs for single or multi-cylinder engines. It holds a market share of close to 80 percent in single-cylinder diesel engines with only one major manufacturer each in the three and four- wheeler segments with captive engines.

As regards hybridisation, though the company recognises the merits in terms of CO2 reduction and fuel economy benefits accruing to customers, cost and complexity in calibration pose a challenge. A hybrid car would require a significantly smaller petrol engine as the motive torque is also supplied by the electric motor. The extent of downsizing will vary on the type of hybrid it is targeting. A full electric vehicle will need a smaller engine as the scope of the engine is limited to charging batteries.

Further, the engine design has to be customised for hybrid vehicles, admits Walia, as the duty cycle changes. He feels the use of single-cylinder or twin-cylinder engines as range extenders would be upcoming market trends in future.

This feature was first published in Autocar Professional's August 1, 2015 print edition

RELATED ARTICLES

Branded content: HL Klemove inaugurates first Local ADAS Radar Manufacturing Unit in India, marks a significant achievement in “Make in India” initiative

The inauguration ceremony was held in the presence of Vinod Sahay, President and CPO of Mahindra & Mahindra Ltd. and Dr....

BluWheelz to 'Green Up' logistics sector

With their EVs-as-a-service solution, the startup is playing it smart with costs and looking to electrify the entire seg...

BRANDED CONTENT: Spearheading the EV revolution in India

Jio-bp is a joint venture between Reliance Industries and BP PLC where both entities have married international expertis...

By Shobha Mathur

By Shobha Mathur

12 Aug 2015

12 Aug 2015

37218 Views

37218 Views