The Verizon IndyCar Series and Dallara, manufacturer of the DW12 chassis used by all IndyCar teams since 2012, confirmed the component failure that sent driver James Hinchcliffe into the Turn 3 wall at unabated speed on Monday at Indianapolis. The possible cause of the failure was also implied in a document distributed to teams preparing for Sunday's 99th running of the Indianapolis 500.

"Based on the initial findings of Mondays incident of the #5 car, we remind teams to inspect the front rockers with the other routinely performed crack checks," the series wrote.

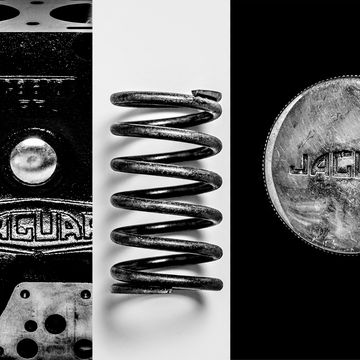

According to the IndyCar technical bulletin, Schmidt Peterson Motorsport's right-front suspension rocker arm (BELOW) did indeed fail on Hinchcliffe's No. 5 car, as was previously reported. The rocker, which connects the suspension at each corner of the car to its damper and spring (BOTTOM), was manufactured in Nov. 2011 and had accumulated 14,000 miles of use.

The rocker was from the thinner, lighter, first-generation units produced by Dallara for the DW12. A thicker, more robust second-generation rocker was produced by Dallara, which most teams purchased and installed when they became available. Use of the second-generation rocker, however, has not been universal.

After learning of the rocker failure, IndyCar called a halt to Monday's practice session and had its teams inspect the age, integrity, and version of those components on each entry. At least three teams were found to have the older first-generation rockers installed, which prompted widespread sales and installations of new, second-generation units. Some teams with the latest rockers also purchased and used new units before practice resumed.

Most modern racing teams track the usage and mileage of each component – from rocker arms to gear ratios to wings – through a computer-based parts lifing system. Whether it's through manufacturer-supplied maximum life thresholds, or institutional knowledge gained by the team, each part is commonly assigned a mileage limit before it is replaced. And with metal components, routine inspection for fatigue is carried out, known as "crack checking." Between each team's internal lifing system and crack inspections, component failure from age or fatigue is usually prevented.

On the surface, 14,000 miles on Hinchcliffe's suspension component seems incredibly high, but in a poll of big and small teams on Gasoline Alley, the use of high-mileage suspension rocker arms wasn't as rare as expected.

Due to the sensitivity of the topic, teams were willing to provide information on their lifing practices, but did not want their team names revealed.

One leading entrant said: "5000 (miles) for us and crack checking after each use." Another said: "Crack inspection prior to each oval event, but we have not mileaged out any rockers. Also, we don't use the [first-generation] rockers."

A third team principal went into greater detail on the subject.

"I think you'll find that mileage figure quoted for the rocker that failed isn't all that unique among teams," he said. "It wasn't a part that anyone had issues with before, but based on the data we were shown by IndyCar, we changed some of rockers out for new before we went back out for Monday's practice. We thought it was prudent – go overkill – and swap some parts out."

He also went on to say that due to Hinchcliffe's crash, IndyCar teams should revisit their lifing programs and reconsider any components like suspension rocker arms that might, for some, have fallen into a comfort zone.

"We all pay a lot of attention to suspension pieces, but then we get a wakeup call with something we thought was bullet-proof," he continued. "Then we did a reset after James crashed. We stepped back, did an overview on parts in general on tracking part mileage and lifing for those parts.

"Maybe that's a part that didn't get as much attention as other parts of the car, but if you get focused on that part, you can get too busy and fail to look elsewhere. You don't want to get in a panic on rockers and fail to look at other items that might have received less attention than they might deserve. I think we all came away with an understanding that we cannot take any part for granted."

Calls to SPM to inquire about their lifing practices went unanswered, and it's unclear whether IndyCar will mandate the use of new (or newer) second-generation rocker arms for the DW12.

This article originally appears at RACER.com. It is republished here with permission.