Mbe Coal And Mineral Technology Gmbh Announces Appointment Of New Global Ceo

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Company Announcement - MBE Minerals SA parent company MBE Coal and Mineral Technology GmbH has appointed Hans George Schnabel as Global CEO of the CMT Group. His appointment is expected to renew the focus on the growth and expansion of the CMT Group globally Schnabel, a graduate engineer from the Technical University of Cologne, has 40 years’ experience in the minerals and metals industries. Formerly head of Andritz Separation GmbH, he has been instrumental in growing the business threefold over the last six years, with a main focus on Africa as a key area of growth and expansion.

Schnabel was previously managing director of KHD Humboldt Wedag’s South African operation from 1988 to 1992. From 1992 onwards Schnabel worked for six years as a board member of KHD AG Germany. His extensive portfolio also includes stints as managing director of Eisenbau Ferrostaal AG, Essen from 1998 to 2000 and President of Outokumpu Technology GmbH from 2000 to 2003. MBE Minerals SA is a leading supplier of iron ore and coal beneficiation technology offering basic and detailed engineering, components for complete plants and systems including modernisation and capacity increase measures as well as automation and process control equipment.

In addition, MBE Minerals SA offers a full scope of services including feasibility studies, raw material testing, financing concepts, erection and commissioning, personnel training and pre- and aftersales services. “We have an extensive reference base throughout Africa and in all the major commodity sectors. Our technology has set the benchmark in many instances,” Johannes Kottmann, managing director of MBE Minerals SA says. Kottmann will report to Schnabel.

MBE Minerals SA receives expertise and technical support from its worldwide network including the MBE Coal and Minerals Technology’s R&D centre in Cologne, Germany. The R&D centre consults with customers from all parts of the world with regard to optimum processing.

This service is backed up by an in-house laboratory facility and pilot test work capabilities. The centre is also used as a training facility for customers, either on general mineral processing or on the operation and maintenance of specific MBE equipment.

Extensive, field tested product range

Focused on delivering best practice solutions to industry, MBE Minerals has a range of products designed with high quality levels, reliability and durability in mind. “Pneuflot® technology from MBE Minerals SA continues to attract global attention as a flotation technology of the future, already surpassing the popularity of conventional technology, with 82 installations in coal globally and magnetite and haematite (itabirite) flotation in South Africa,” Kottmann says.

The Pneuflot® flotation cell improves product quality and recovery, delivering lower capital and operating costs, as well as significantly lower wear costs and higher efficiencies, which are key criteria in the African mining industry as major mining houses seek to boost productivity and cut costs.

MBE Minerals SA’s BATAC® jig technology delivers higher efficiency, huge economic benefits, better product quality, better machine availability and higher throughput rates. Advantages derived from using this technology are excellent separation accuracy, a relatively small footprint and comparatively low capital cost. Accuracy is achieved through electronic control of the air pulse generator and sensing of the thickness and densities of the material layers being separated.

MBE Minerals SA’s ROMJIG® is particularly suited to the reliable and economical destoning of raw coal. Due to the lower percentage of refuse in the washery feed, there is a resultant reduced wear on machinery and transporting equipment, less grain degradation, less dust and slurry and reduced consumption of flocculation and flotation agents in downstream fines recovery circuits. Operating at up to 14 500 Gaus, the company’s robust Jones® Wet High Intensity Magnetic Separator (WHIMS) offers a high throughput capability, coupled with simple maintenance and lower energy consumption. The WHIMS is perfect for treating feebly magnetic minerals with a particle range from 20 microns up to 1.5 mm with unit throughput capacities from 500 kg/h up to 250 tph.

The Permos® Medium Intensity Magnetic Separator drum type unit is suitable for materials which can be attracted by a field strength of between 2 000 and 5 000 Gaus. Designs for both dry and wet feeding are available from MBE Minerals SA. The Palla Mill® is suitable for both wet and dry applications in primary and secondary grinding and for pulverising materials of any hardness. It is capable of grinding more than 100 different materials, including a range of minerals and commodities previously considered unviable due to the costs involved.

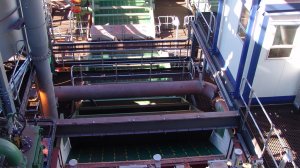

A variety of vibrating screens is available in widths of up to 3.6 m and lengths of up to 6.75 m with single or double deck configuration and in either circular or linear motion. Screens can be provided for sizing, scalping, dewatering and media recovery, and feature an innovative side plate mounted drive which makes them lighter than those using vibrator motors. The TESKA separator from MBE Minerals SA performs dense media separation in a suspension of finely ground solids and water. In this kind of media, particles of high specific gravity settle at the bottom, while particles of lower specific gravity float, such as coal.

Flexibility in design centred on market needs is complemented by a focus on manufacturing to the highest possible quality standards. MBE Minerals South Africa’s future growth trajectory is directly aligned with its ability to adapt to application-specific requirements and to drive pioneering technology for the mining and quarrying sectors.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation