Abstract

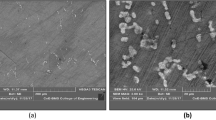

The investigated material is the copper-free Al–Zn–Mg-alloy EN AW-7020 (AlZn4,5Mg1) in the artificial aged T6 temper. In this temper the 7xxx series alloys show a high strength level, but also a high stress corrosion sensitivity. Therefore, the retrogression and reaging (RRA)-treatment has been developed to combine stress corrosion resistance with high strength. The aim of this study is the description of the course of the mechanical behavior influenced by a RRA treatment. The changes of the mechanical properties are represented by changes in the microstructure as recorded by thermal analysis. Therefore typical mechanical properties and thermal analysis curves are determined according to temperature and time in each of the retrogression annealing and of the RRA-treatment. The temperature for retrogression annealing was between 220 and 360 °C. Reaging was performed on material at 130 °C for 16 h and 160 °C for 5 h after a storage of 7 days at room temperature. The results of the thermal analysis are generally described on the curve of the T6 tempered material and transferred to the changes by the retrogression temperature and the reaging parameter. The results show a main influence of the precipitation structure and mechanical properties after the retrogression and reaging treatment by the temperature of the retrogression annealing. For all investigated parameters, an overaging of the material after the RRA-treatment is recognizable.

Similar content being viewed by others

References

Loeffler H, Kovacs I, Lendvai J (1983) Decomposition process an Al–Zn–Ag alloys. J Mater Sci 18:2215–2240

Cina BM (1974) Reducing the susceptibility of alloys, particularly aluminium alloys to stress corrosion cracking, US patent 3856584 A

Park J, Ardell A (1984) Effect of retrogression and reaging treatment on the microstructure of Al-7075-T651. Metall Mater Trans A 15:1531–1543

Ural K (1994) A study of optimization of heat-treatment conditions in retrogressions and reageing treatment of 7075-T6 aluminium alloy. J Mater Sci Lett 13:383–385

Ohnishi T, Ito T, Ibaraki Y (1989) Improvement of fracture toughness in 7475 aluminum alloy by the RRA (retrogression and re-aging) process. Mater Trans JIM 30:601–607

Viana F, Pinto AMP, Santos HMC, Lopes AB (1999) Retrogression and reaging of 7075 aluminium alloy: microstructural characterization. J Mater Process Technol 92–93:54–59

Rajan K, Wallace W, Beddoes JC (1982) Microstructural study of a high-strength stress-corrosion resistant 7075 aluminium alloy. J Mater Sci 17:2817–2824

Baldantoni A (1985) On the microstructural changes during the retrogression and reaging of 7075 type aluminium alloys. Mater Sci Eng 72:L5–L8

Jaburek N, Merklein M (2013) Study of a formability process chain for a copper-free Al–Zn–Mg-alloy by a retrogression and re-aging treatment (RRA). Key Eng Mater 549:295–301

Jaburek N, Merklein M (2014) Influence of a regression heat treatment on the material properties of a copper-free 7xxx series aluminium alloy. Procedia CIRP 18:108–113

Delasi R, Adler PN (1977) Calorimetric studies of 7000 series aluminum alloys: I. Matrix precipitate characterization of 7075. Metall Mater Trans A 8:1177–1183

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jaburek, N., Merklein, M. Influence of a retrogression and reaging (RRA)-treatment on the mechanical and microstructural characteristics of the aluminium alloy AlZn4,5Mg1. Prod. Eng. Res. Devel. 9, 161–166 (2015). https://doi.org/10.1007/s11740-014-0593-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-014-0593-4