CRANSTON, RI, Feb. 12, 2015 -- Primary Flow Signal (PFS), a designer and manufacturer of durable and accurate flow metering solutions, has successfully installed a rectangular Halmi Venturi Flow Meter at the Blue Plains Advanced Wastewater Treatment Plan in Washington, D.C., in an effort to accurately measure sewage discharge from the facility.

According to the District of Columbia Water and Sewer Authority (DC Water), the Blue Plains utility, covering 150 acres, is the largest of its kind in the world, with a capacity of 370 million gallons per day (MGD) and a peak capacity of 1.076 billion gallons per day. The plant provides wastewater collection and treatment services to more than 2 million Washington metro area customers.

PFS collaborated with Black & Veatch to assess DC Water's flow metering requirements for treatment of sewage that will eventually flow back into the Potomac River and ultimately the Chesapeake Bay. Due to the unique upstream configuration and extremely low pressure within the channel (5 psi), PFS performed scale model testing that validated the projected accuracy and headloss of the meter, despite the significant physical, dimensional and low-pressure challenges of the flow channel.

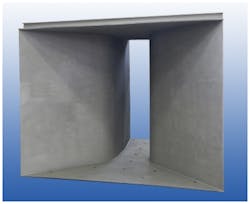

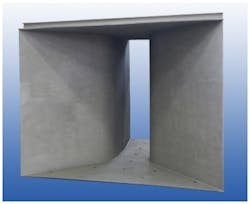

At its facility in Rhode Island, for example, PSF manufactured a full-size rectangular Halmi Venturi Flow Meter, which was installed by Ulliman Schutte Construction with assistance from PSF's personnel. Once installed, grouting and concrete work ensured a smooth flow through the meter. This was vitally important as the low pressure in the channel made headloss a significant concern for maintaining accuracy.

"The Blue Plains project presented an opportunity for us to collaborate with the Authority's internal engineers and Black & Veatch to come up with what is, frankly, the only solution possible for this particular application," said Gary Gilbert, PSF senior principal engineer. "From initial planning, model testing, manufacturing, installation, to final acceptance, this important project validated our approach to ensure the meter will meet and exceed its projected performance."

Halmi Venturi Flow Meters are rugged, reliable, differential pressure measurement devices, designed to measure full pipe flow of gases or liquids over extreme temperature ranges, as well as contaminated liquids, sludges, slurries, and sewage. The meters are available in a variety of materials, including a cast iron pressure vessel, fabricated (welded) metal pressure vessel, plastic insert style, welded insert, and welded-in pressure vessel. Additionally, they are offered with a cast-in-place design (usually concrete and typically rectangular), depending upon the application.

See also:

"Venturi Meters: The Headloss Benefits of a Simplistic Design"

"Tracking the Flow: Meeting the Challenge of Open-Channel Flow Measurement in Municipal Applications"

About Primary Flow Signal

PFS is a vertically integrated, global resource providing design, engineering, calibration, manufacturing, and application support for a wide range of differential producer type flow primaries in numerous markets and industries including oil & gas, power, municipal water/wastewater, process control, and diesel gas flow measurement. PFS is part of an operating unit, which delivers proven differential and turbine meters, and fire suppression solutions. Its U.S. offices are located in Rhode Island; Houston and Odessa-Midland, TX; Tulsa and Altus, OK; Seneca, SC; and Bakersfield, CA. For more information, visit: www.primaryflowsignal.com.

###