Virtual reality: new software for mining trucks

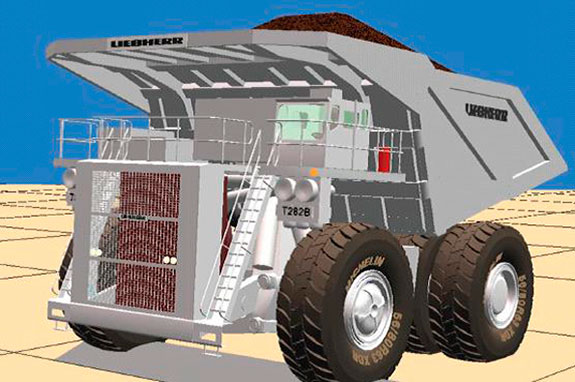

Solutions from Siemens PLM Software LMS Virtual.Lab are helping mining machinery manufacturer, Liebherr, in its search for design alternatives. By running complete vehicle simulations, it has been able to increase the payload of its TC282 C mining truck with minimum time and effort.

In the mining industry of today, the primary objective for mining truck operators is to reduce empty vehicle weight in favour of an increased payload.

To meet rising demand for metals, mining trucks are required to transport ever-higher loads of these valuable raw materials. The Liebherr Group, an international mining machinery supplier based in Bulle in Switzerland, has succeeded in reducing the overall weight of its giant T282 C mining truck, thereby allowing for an increase in payload.

Instead of relying on physical models, the company took a different approach to the optimisation process. By using LMS Virtual.Lab simulation software, it was able to combine all the designs of the individual groups of engineers working on the project to create a single cohesive overall model. Siemens PLM Software generated a dynamic multibody simulation model, which integrated the mining truck’s components and units as multibody elements complete with their geometric and material properties.

Rapid problem diagnosis

The technical challenge posed here lay in the truck’s design, which had to allow efficient operation under even the toughest of application conditions and in different types of terrain. LMS Virtual.Lab reconstructed the mining truck’s behaviour under different loads, allowing the engineers to estimate the efficiency of the truck components and identify potential problem areas. The simulations were evaluated using a finite element analysis. On the basis of the test results, the engineers were able to implement improvements to truck components and their mechanical design in the model.

The LMs Virtual.Lab software is capable of rapidly simulating different terrain conditions and integrating them into a multibody model.

Following the first simulation runs, multibody loads for the final design were imported into the LMS Virtual.Lab durability software, with a view to also determining the fatigue life of crucial truck components.

Outlining the benefits of the software, the Head of the Liebherr Group’s Mining Truck Analysis and Simulation Division, Dr Vladimir Pokra, explained: “We were able to find alternative designs which would have been highly laborious to determine using physical models. The ability to quickly integrate additional details into the model means that we can generate multibody models more quickly and with less risk of error than if we had to start from scratch again every time.”

Edited by Sam Dodson

Read the article online at: https://www.worldcoal.com/mining/29012015/vehicle-simulation-software-for-mining-trucks-1816/

You might also like

EIA reduces its forecast for US coal exports following Port of Baltimore closure

The US EIA has decreased its forecast for US coal exports following the collapse of the Francis Scott Key Bridge and the resulting closure of the Port of Baltimore.