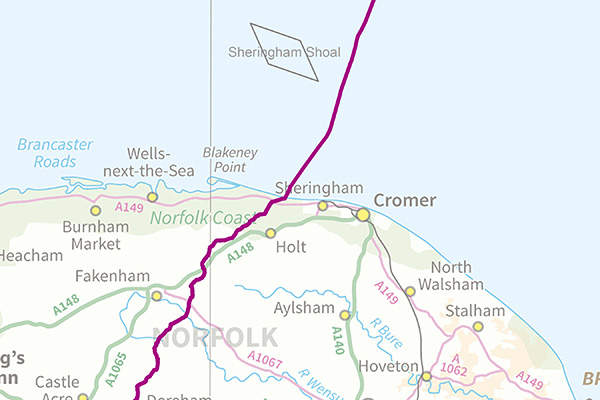

The 402MW Dudgeon offshore wind farm, developed approximately 32km off the coast of Cromer, North Norfolk, in the UK North Sea, is one of the world’s biggest offshore wind farms.

Statoil holds a 35% stake in the project and is the operator. Masdar also owns 35%, while Statkraft holds the remaining 30%. Construction of the £1.5bn ($2.5bn) wind farm began in March 2015, and the commercial operations began in February 2017. The wind farm was officially inaugurated on 22 November 2017.

The wind farm will produce approximately 1.7TWh of clean energy annually, which will power approximately 410,000 UK households. It will also offset 19mt of carbon dioxide emissions from the atmosphere over its 25-year lifetime.

The project has created approximately 70 jobs during its operations.

Dudgeon wind project background

The UK Government granted the licence for the 560MW offshore wind farm development at the Dudgeon site during the Round II allocation in 2003. The project received planning consent from the Department of Energy and Climate Change (DECC) in 2012.

Statoil and Statkraft acquired the project from Warwick Energy in 2012 and reviewed the design, eventually reducing the generating capacity to 402MW. The revised proposal was approved by the DECC in December 2013.

Wind farm turbine details

The Dudgeon offshore wind farm includes 67 Siemens 6MW wind turbines installed on monopile foundations at water depths ranging between 18m-25m.

Each turbine has a rotor diameter of 154m with 75m-long rotor blades manufactured using single-cast Siemens Integral Blade production technology.

The turbines are rested on monopiles with a diameter between 7m and 7.4m, which weigh between 800t and 1,200t. The operations and maintenance base for the wind farm is situated at Great Yarmouth Port’s river harbour.

Power transmission from Dudgeon wind farm

The power generated by the offshore wind farm is transported to the shore at Weybourne Hope on the North Norfolk coast by a 38km-long, 132kV seabed cable. A 48km-long underground cable transfers the electricity to the Necton substation, which is built near Swaffham Town, Breckland, Norfolk. From here, the power is transmitted to the National Grid network using a 400kV overhead line.

Dudgeon wind farm construction

Onshore cable construction works started in March 2015, and the offshore foundation installation, testing and commissioning started in 2016. The monopile foundations were installed using Seaway Heavy Lifting’s crane vessel Oleg Strashnov.

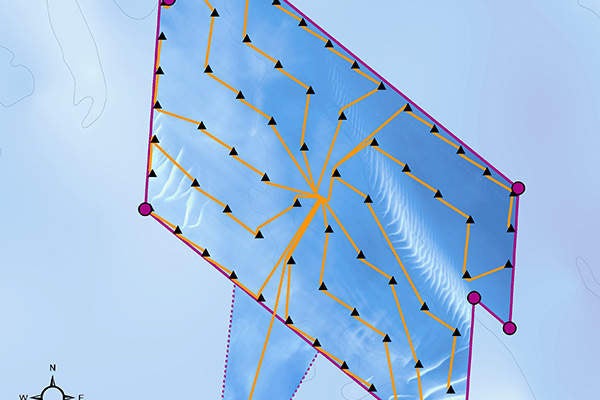

The inter-array cables, which are equipped with hang-off termination technology, were pulled inside the monopile foundations to connect the turbine generators with the offshore substation.

The export cable was loaded onto a cable installation vessel in Karlskrona, Sweden, and laid between pre-drilled ducts in the landfall area towards the offshore substation.

Contractors involved

Siemens was awarded the contract for the engineering, supply, commissioning and service of 67 wind turbines for the Dudgeon wind farm. In addition, the company was awarded a turnkey contract in September 2014 to deliver the grid connection for the project.

The contract for the fabrication of the monopile foundations was awarded to Sif Group, while Atkins provided the monopile foundation engineering and management assistance. RG Carter was selected to build the onshore operations and maintenance base, while the installation contract of the wind turbine generators was awarded to A2SEA.

ABB was awarded the engineering, procurement and construction (EPC) contract for the submarine export cables. Seaway Heavy Lifting was awarded the monopole foundations and offshore substation installation contract. A five-year service operation vessel contract was awarded to Esvagt.

Visser and Smit Marine Contracting (VSMC) was awarded the engineering, procurement, construction and installation (EPCI) contract for the export and inter-array cables. The inter-array cables were designed and supplied by JDR.

Carillion was responsible for the underground cable construction and installation.