Using the right oil not only protects and prolongs the life of a vehicle’s engine and improves its performance, but can also help the owner save on maintenance and fuel costs. Benchmarking its products on those parameters, Shell Lubricants in India is riding piggyback on its ‘Rimula’ range of products which has been specifically developed for bus and truck applications.

It is to be mentioned here that the Indian arm of Royal Dutch Shell plc has already allied itself with some of the marquee CV clients like VECV, Tata Motors, BharatBenz, etc. Globally, the Anglo-Dutchmaker also has close associations with Isuzu, Scania, MAN, Daimler, etc. Among its current client base in India, nearly 50 per cent is derived from the industrial division and the remaining half from the automotive division. Within the automotive division, it is also serving car and two-wheeler OEMs in the country.

In an exclusive interaction with MOTORINDIA, Mr. Nitin Prasad, Managing Director, Shell Lubricants – India, Bangladesh and Sri Lanka, stated: “Since our foray into the Indian lubricants business in 1993, we gained a strategic foothold in the commercial vehicle industry. Our key brands include Rimula, Spirax and the Gadus, which cover oils for engines, transmissions, axles as well as greases. We have a range of products – Shell branded products, co-branded products and OEM marketed/distributed genuine products. We are betting big on Rimula’s portfolio of products comprising R1 Multi (CF), R2 Extra (CF4), R3X (CH4) and R4 (CI4+) for commercial vehicle applications. Rimula’s advanced technology works by adapting physically and chemically to the toughest conditions within the engine, no matter how hot, cold, steep or rocky the road may be delivering the best performance. As a marketing exercise, we had also rolled out the ‘Shell Rimula Mera Humsafar, Meri Kahaani’ campaign to recognize and reward the hardworking trucker community.”

He further observed: “We have recently rolled out Rimula R4 which caters specially to modern engines with EGRs to handle excess soot and viscosity increase. It is basically a CI4+ enabled oil which was developed specifically for the Indian market. Using this oil results in upto 61% better wear protection*. This product has been very well accepted in the market.”

The Shell Rimula R4 technology is designed to protect modern engines with turbo-chargers, inter-cooling and exhaust gas recirculation from the high-pressure contacts in the valve train to the extreme temperatures of the pistons and rings. Shell Rimula R4 adapts to all the conditions and within the vehicle’s engine, and helps the owner to minimize the vehicle’s maintenance and operating costs by providing a versatile one-oil solution for modern fleets.

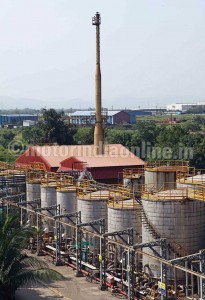

Among its existing product lines, Shell Rimula R3X Energized Protection oil provides triple action protection against wear, deposits and heat, continuously adapting to the needs of a vehicle’s engine. It provides upto 35 per cent lower engine wear**. Most, about 90 per cent, of Shell Lubricants’ products are blended locally in a world class lube oil blending plant (LOBP) at Taloja near Mumbai (established in 1997 and spread over an area of 16 acres) and some products are imported, especially synthetic lubricants.

Talking about the company’s future course of action, Mr. Prasad observed: “Going forward, we will be actively working on next generation CI-4 / CI-4 + oils which will augment the wear protection with improvements in fuel efficiency. At the same time we are planning to launch the next generation of semi-synthetic and synthetic lubricants that will extend the oil drain interval beyond the current levels of 40,000-50,000 km. The pace of change in India is one of the fastest ones globally, e.g., the rapid migration from 20,000 km oil drain intervals but, having said that, a lot of catching up still needs to be done as compared to global markets. As the country switches from BS-IV to BS-V (after 2015), which will require more stringent emission controls, we have seen that a close collaboration is needed between manufacturers and Shell to deliver the required specifications, i.e., lubricant design becomes an essential part of the initial vehicle and engine design.”

Shell Lubricants believes its next generation engine oils, Rimula R5 and Rimula R6, will not only enhance the existing Rimula portfolio but will also enable it to strengthen its presence in the aftermarket space. “Rimula R5 is a semi-synthetic solution and R6 is a fully synthetic solution. For these applications, we will work with large fleet operators to lower their maintenance and total cost of ownership costs. We are also planning to have Shell Rimula R6 M which provides excellent protection against acid corrosion, deposits and wear, achieving the extended oil drain performance based on approvals from leading engine makers. I am confident these next-generation products will give us a fillip in the aftermarket segment.”

When asked to shed some light on some of the key growth drivers of the automobile industry in India, Mr. Prasad asserted: “We are betting big on the under-penetrated fleet modernisation among various operators. Furthermore, we are launching oils which improve the TCO, reduce maintenance downcycle and fuel efficiency of the vehicles. We are always working on next-generation oils and are allying with OEMs, dealers, service stations, etc., to be able to create solutions down to all the individuals who make the world move, i.e., the entire commercial vehicle eco-system.”

Shell’s presence in India dates back to 1914 when it operated in the country as the pioneering oil distribution company, Burmah Shell. Set up in 1928, Burmah-Shell Oil Storage and Distributing Company of India Ltd. began operations with import and marketing of kerosene. It pioneered rural marketing by reaching out to people even in remote villages to ensure supply of kerosene.

In 1993 Shell Lubricants came back to the country in joint venture with Bharat Petroleum, and the company was christened Bharat Shell Ltd. The partnership lasted for more than a decade, and by the end of 2007 Shell Lubricants became a 100 per cent subsidiary of Royal Dutch Shell by acquiring the minority stake of Bharat Petroleum. At the same time, Shell Lubricants India merged the Pennzoil brand with its brand portfolio and became one powerful entity in the category. Since 1997, Shell India has been manufacturing its lubricants at its lubricant oil blending plant at Taloja, near Mumbai.

Asked about Shell India’s long-term roadmap, Mr. Prasad said: “BRIC countries are the growth frontiers for Shell. As the 3rd to 4th largest lubricants market, India will be a key focus for future growth and investment over the next 10-15 years.”

Shell is the largest and most diversified international investor in India’s energy sector among all global integrated oil companies with nearly $1 billion invested until now.

* compared to that of Std API CI-4 plus limit

** in on-road heavy-duty testing vs. API CG-4 oils