A photoelectrochemical cell that imitates plant photosynthesis and uses sunlight and water to create synthetic fuels such as hydrogen is being developed by Empa that recreates a moth's eye to drastically increase its light collecting efficiency. Empa is a Swiss Federal interdisciplinary research and services institution for material sciences and technology development within the ETH Domain. Furthermore, the cell is made of cheap raw materials—iron and tungsten oxide.

RELATED ARTICLE: Cheaper materials are key to lower-cost solar cells

Rust (iron oxide)—a typically unwanted substance—can be used to make photoelectrodes that split water and generate hydrogen. Sunlight is thereby directly converted into valuable fuel rather than first being used to generate electricity. Unfortunately, as a raw material, iron oxide has its limitations. Although it is unbelievably cheap and absorbs light in exactly the wavelength region where the sun emits the most energy, it conducts electricity very poorly and must therefore be used in the form of an extremely thin film in order for the water splitting technique to work. The disadvantage of this is that these thin-films absorb too little of the sunlight shining on the cell.

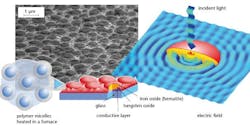

Empa researchers Florent Boudoire and Artur Braun have now succeeded in solving this problem. A special microstructure on the photoelectrode surface literally gathers in sunlight and does not let it out again. The basis for this innovative structure is tiny particles of tungsten oxide that, because of their saturated yellow color, can also be used for photoelectrodes in a photoelectrochemical solar cell. The yellow microspheres are applied to an electrode and then covered with an extremely thin nanoscale layer of iron oxide. When external light falls on the particle it is internally reflected back and forth, till finally all the light is absorbed. All the entire energy in the beam is now available to use for splitting the water molecules.

In principle the newly conceived microstructure functions like the eye of a moth, explains Florent Boudoire. The eyes of these night active creatures need to collect as much light as possible to see in the dark, and also must reflect as little as possible to avoid detection and being eaten by their enemies. The microstructure of their eyes especially adapted to the appropriate wavelength of light. Empa's photocells take advantage of the same effect.

In order to recreate artificial moth eyes from metal oxide microspheres, Florent Boudoire sprays a sheet of glass with a suspension of plastic particles, each of which contains at its center a drop of tungsten salt solution. The particles lie on the glass like a layer of marbles packed close to each other. The sheet is placed in an oven and heated, the plastic material burns away and each drop of salt solution is transformed into the required tungsten oxide microsphere. The next step is to spray the new structure with an iron salt solution and once again heat it in an oven.

In parallel with their practical experiments, the researchers have been running calculations modeling the process on their computers and are able to simulate light capture in the tiny spheres. The results of the simulation agree with the experimental observations, as project leader Artur Braun confirms. It is clear to see how much the tungsten oxide contributes to the photo current and how much is due to the iron oxide. Also, the smaller the microspheres, the more light which lands on the iron oxide underneath the tiny balls. As a next step the researchers plan to investigate what the effect of several layers of microspheres lying on top of each other might be.

SOURCE: Empa; http://www.empa.ch/plugin/template/empa/3/148620/---/l=2