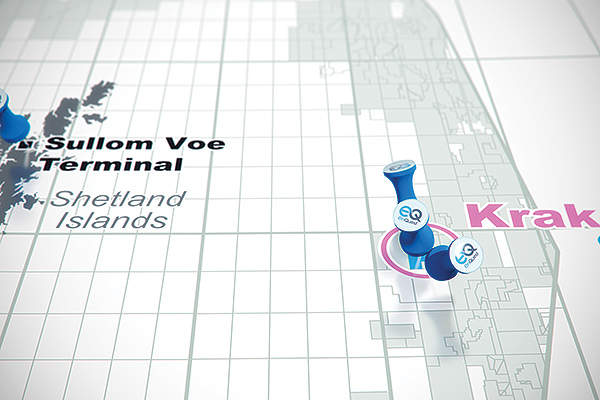

Kraken is one of the biggest subsea heavy-oil field projects in the UK sector of the North Sea. The field lies at a water depth of 120m in blocks 9/2b and 9/2c within the P1575 licence in the East Shetland basin, which is located 125km away from Noss.

EnQuest Heather is the operator and owns a 60% interest in the asset. The remaining stake is co-owned by Cairn Energy (25%) and First Oil (15%).

EnQuest received a £4bn investment approval for the development of the Kraken field from the UK Department of Energy and Climate Change (DECC) in November 2013, and the field came on stream in June 2017.

Kraken field production and oil reserves

The Kraken field is estimated to hold reserves of 137 million barrels of heavy oil, with an anticipated field life of 25 years. At its peak, it is expected to produce more than 50,000 barrels per day (bpd).

Discovery and development

Nautical Petroleum discovered the site in 1985. In November 2007, the first appraisal well 9/2b-2 drilled to a total depth of 4,378ft and discovered oil-bearing Paleocene Heimdal sands.

The second appraisal well, 9/2b-3, was drilled by a Sedco 704 semi-sub in September 2008, although the Heimdal sandstone was absent in the reservoir.

EnQuest purchased a 25% stake from Nautical Petroleum in January 2012, and then became the operator of blocks 9/2b and 9/2c after acquiring 15% of the shares from First Oil in April of the same year.

The company plans to develop the area into three different fields, namely Kraken North, Kraken Central and Kraken South, which are located in block 9/2b.

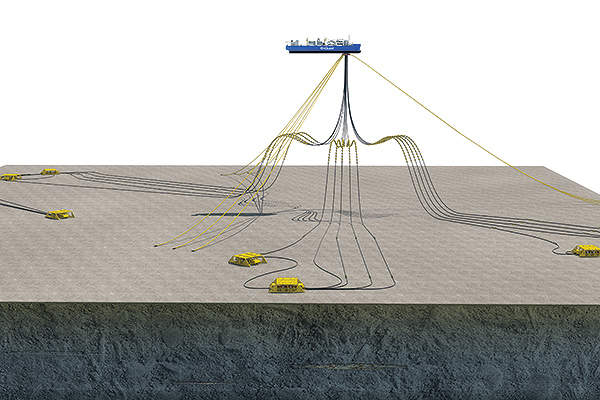

FPSO development at the field

The floating production, storage and offloading (FPSO) vessel was developed by converting a Suezmax ice-class tanker at the shipyard in Singapore in the second quarter of 2015. It has a total storage capacity of 600,000 barrels and was moored by a buoy-turret mooring system. The vessel is connected with 16 risers, which have a fluid transfer system at 390 bars of pressure.

Export tankers ship the crude oil from the vessel by using a tandem offloading process. The FPSO vessel was arrived at the field in February 2017 and started producing oil in June 2017.

Designed to handle flow rates of up to 460,000bpd, it accommodates up to 80,000bpd of oil and 20MMscf of gas, in addition to 275,000bpd of water to be used for the injection.

The total installed power of 62MW is divided into four 15.5MW configurations, while the power plant features a triple fuel system involving the direct burning of heavy crude oil. The oil is produced using hydraulic subsea pumps (HSPs), which require reduced maintenance.

Contractors involved

In November 2013, SPX Corporation was awarded a $22m contract for the supply of the HSPs, which are used for the production of oil from the wells. Utilised for artificial lift service, these pumps, raise the pressure of reservoir fluids to allow an optimised flow of heavy oil production to the FPSO facilities.

In December 2013, Bumi Armada subsidiary Armada Kraken won two contracts collectively worth $1.4bn to deploy, operate and maintain the FPSO facility. The contractual term is for a period of eight years, with an option for 17 annual extensions.

Wärtsilä won the right to supply a 62MW topside power module solution in January, and the equipment deliveries were completed in 2015.

In February 2015, Deltamarin was contracted to provide the basic design for the vessel, having earlier provided the technical support for the conversion of the Suezmax ice-class tanker into an FPSO during the front-end engineering design (FEED) phase.

The work involves further development of the FEED phase material into a class-approved FPSO basic design, which includes naval architecture, structural and strength analysis, and steel outfitting.

This also incorporates designs for marine, utility, HVAC, accommodation, HSE, and electrics and instrumentation, with the work completed in six months.